Looking for more information on Vendor Managed Inventory (VMI)? You would lose the opportunity to maximize sales and support customer interests. If your consumers show a sudden surge in demand for a particular product, the JIT system might be unable to meet it.

However, JIT has a few risks that reduce its effectiveness. The Risks of Relying on JIT for Inventory Management Overall, the advantages of just-in-time inventory can enhance your overall warehousing and organization methodology. You only pay for the items that are guaranteed to sell, reducing financial risk. P rotects investments: The JIT model requires less working capital, optimizing your return on investment (ROI).Storage of items like tires and engines can quickly become expensive, but JIT reduces the need for warehousing. JIT is especially beneficial in industries with bulky items, like the automotive industry. You only order when a customer places an order, making lengthy storage unnecessary. In some cases, you could eliminate the need for warehousing entirely. With the JIT model, you keep warehousing costs to a minimum. If the inventory goes to waste, the extra payments become entirely wasteful. Lowers holding costs: Excess inventory can double your warehousing costs, leading to heightened monthly costs.You can notice defects more quickly and ensure your available stock is high-quality. Fewer stock numbers also allow you to dedicate more individualized attention. You maintain adequate inventory space and only spend money on the items you need. In turn, you remove the risk of overordering and accumulating excess stock.

You only order exact quantities based on customer orders.

JIT inventory provides many advantages for supply chain companies wanting to improve inventory management. By implementing a vendor managed inventory (VMI) solution, you can maximize the benefits of JIT and reduce risks. Managers should weigh the just-in-time advantages and disadvantages to understand if the strategy best meets your company's needs.

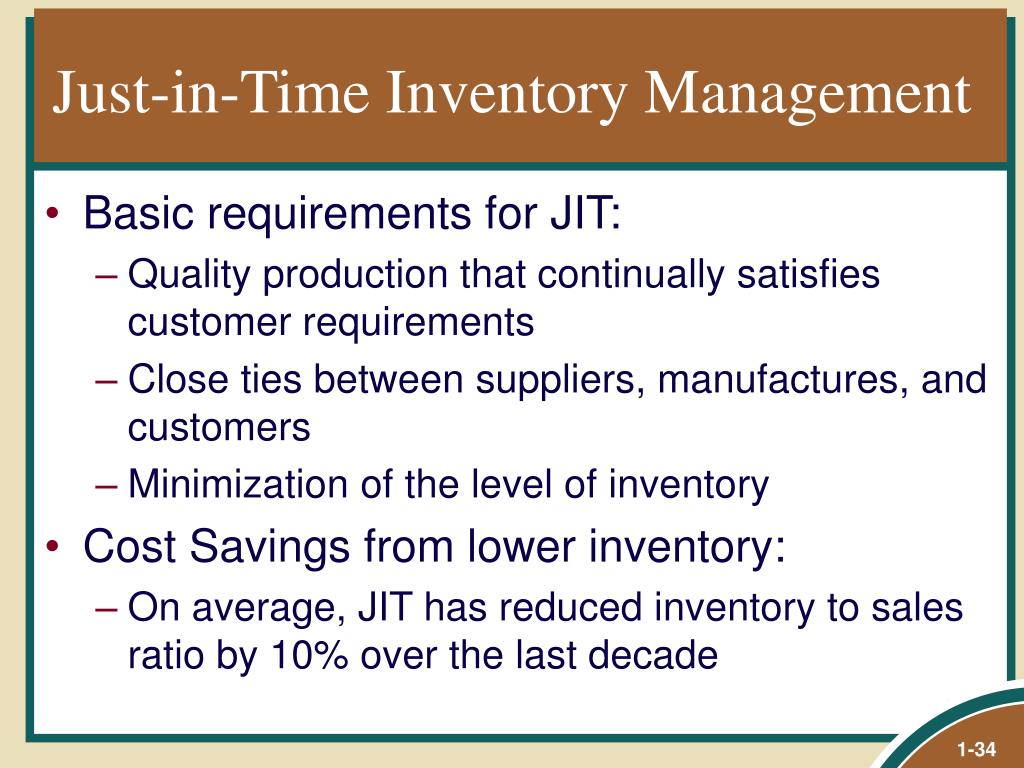

While JIT has many benefits, it also has a few notable drawbacks. In turn, you can reduce inventory holding costs and overall waste throughout the supply chain. This strategy keeps the minimum amount of stock on hand instead of stockpiling products. One notable strategy for inventory management is just-in-time (JIT) inventory.

Just in time inventory software#

Supply chain management software remains a rapidly growing field, and supply chain managers continue to find new strategies to meet changing demands, boost efficiency, and cut costs. Become a TrueCommerce Reseller or Partner.Integration with Any Other Business Systems.

0 kommentar(er)

0 kommentar(er)